PRODUCTION AUTOMATION

- manufacturing facilities

- installation facilities

- material transport

- component supply

- processes of forming, stamping and joining

- forming, punching,

pressing

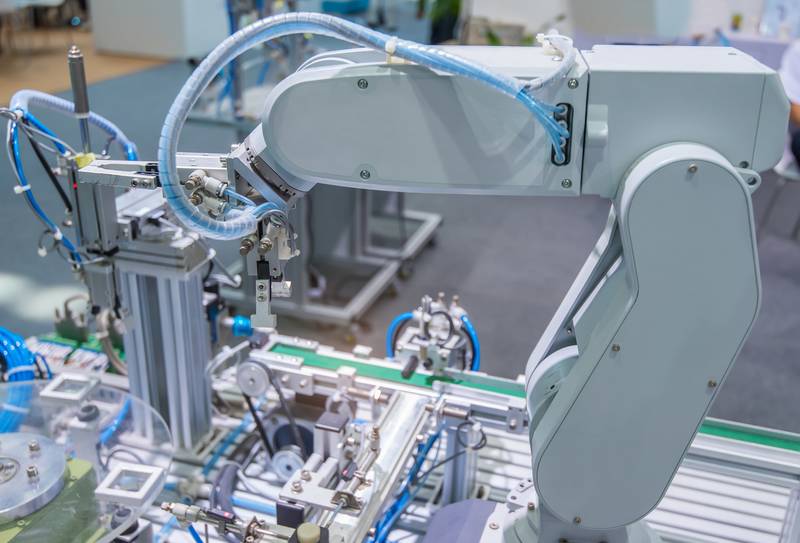

ROBOTIC SYSTEMS

- for handling operations

- in material transport

- for SGM loading and unloading

- for installing and inserting

- for palletizing

- high flexibility through the use of micro robots

TESTING TECHNOLOGY

- Functional tests

- component testing

- Leak tests

- Flow tests

- level measurement

EQUIPMENT

- Special tools

- Handling aids / manipulators

- assembly fixtures

- gauges

- Test Equipment

CONSTRUCTION

- 3D-CAD-design

- concept development

- Product development

- Process analysis / optimization

- Preparation of profound technical documentation

- work preparation

ELECTRICAL DESIGN

- construction by EPLAN electric P8

- Use of modern decentralized periphery

- Control cabinet construction in house

- Electric installation in house

- Modernization of existing facilities

PROGRAMMING

- Siemens S7 200/300/400/1200/1500 with S7 Classic or in the TIA Portal

- Siemens HMI with WinCC Advanced

- Drive systems from SEW / Siemens or according to customer specifications

- Robots from Kuka, Omron, ABB

- Camera systems from Cognex / Keyence / Sensopart

- Bus systems PROFIBUS / PROFINET / IO-LINK

- Programming languages: STL / LAD / FBD / SCL / S7-Graph usf.

MANUFACTURING AND INSTALLATION

- modern CNC milling technology

- CNC lathe

- MAG / TIG welding assemblies

- complete installation in your house

- Highly qualified staff

- optimized production and adaptation through short communication paths

- uncomplicated modifications

INSTALLATION

- Pre-acceptance with the customer before delivery

- Final acceptance by the customer after delivery

- Production support

- Employee training

- Support and remote maintenance

- removal / conversion

WORLDWIDE

We deliver our systems worldwide, e.g. B. in the USA, China and Mexico, manufactured according to the applicable country-specific standards and guidelines.